Aluminum Scrap Price & Recycling

GET INSTANT CASH FOR ANY SCRAP, ANY CAR!

SELL YOUR SCRAP METAL

About Aluminium & Price

It’s called aluminum by the Americans and aluminium by the British, but everyone agrees that it’s the third most abundant element in the world next to oxygen and silicon. About 8 percent of the world’s mass is made up of it. But you can’t find it naturally in pure form. In the Earth’s crust, it is part of a compound called alum.

A Danish chemist was first able to extract aluminum from alum in 1825. Succeeding scientists were able to improve the process for years afterwards, but the difficulty of extracting the metal made it more valuable than gold. Napoleon III, who was president of the French Second Republic in 1848, honored his guests by offering aluminum cutlery and plates for dinner use. The les important guests had to use gold cutlery. In 1884, the Washington Monument was capped with it because of the value of the metal at the time.

Then in 1886, a chemistry graduate named Charles Hall and a French engineer named Paul Heroult separately came up with the process to extract the metal more efficiently. This Hall-Heroult method is still used today to produce aluminum.

Aluminum can recycling

Aluminium can be 100% recycled. Aluminium recycling is the process by which aluminium scrap can be reused in products after its initial production. The process involves simply re-melting the metal, which is far less expensive and energy-intensive than creating new aluminium through the electrolysis of aluminium oxide (Al2O3), which must first be mined from bauxite ore and then refined using the Bayer process. Scrap aluminium recycling requires only 5% of the energy used to make new aluminium from the raw ore.

Aluminium is an infinitely recyclable material, and it takes up to 95 percent less energy to recycle it than to produce primary aluminum, which also limits emissions, including greenhouse gases. Today, about 75 percent of all aluminum produced in history, nearly a billion tons, is still in use. Aluminium recycling generally produces significant cost savings over the production of new aluminium, even when the cost of collection, separation and recycling are taken into account. Over the long term, even larger national savings are made when the reduction in the capital costs associated with landfills, mines, and international shipping of raw aluminium are considered.

5 Steps of Aluminium Recycling

Aluminum can recycling in five steps:

- collecting scrap;

- sorting scrap;

- crushing;

- remelting; and

- casting.

Aluminium scrap is the most essential input material to the

Aluminium recycling process.

Aluminium scrap is often categorised as “new scrap” from production processes and “old scrap” from post consumer use.

New scrap arises during the manufacturing of aluminium semi-fabricated and final products. Old scrap aluminium refers to those products collected after disposal by consumers. Old aluminium scrap is often more contaminated than new scrap. End-of-life vehicles, demolished buildings and constructions, discarded packaging material, home and office appliances, as well as machinery equipment are all potential sources of old aluminium scrap.

The collection and sorting of scrap aluminium , aluminium cans, especially old scrap, is often a complex scheme involving millions of households, local and regional authorities, small and medium collectors and metal merchants. Waste and environmental policies can also have strong influences on the effectiveness of collection schemes.

Sorted scrap aluminium may need to be separated further and pre-treated before the metal can be recovered in melting furnaces. Separation of aluminium at this stage can be done by various mechanical operations, such as magnetic, gravity, eddy current, or colour sensor. Further separation of different aluminium alloys can also be achieved through x-ray methods. Often wrought alloys and casting alloys are, whenever possible, separated before the mechanical processes.

Other input materials are also required to transform valuable aluminium scrap into aluminium metal. Alloying elements are crucial to the wide range of functionalities and characteristics of aluminium products. In refining scrap aluminium , impurities that cannot be removed by mechanical separation will be eliminated through the addition of salt flux in the melting furnaces.

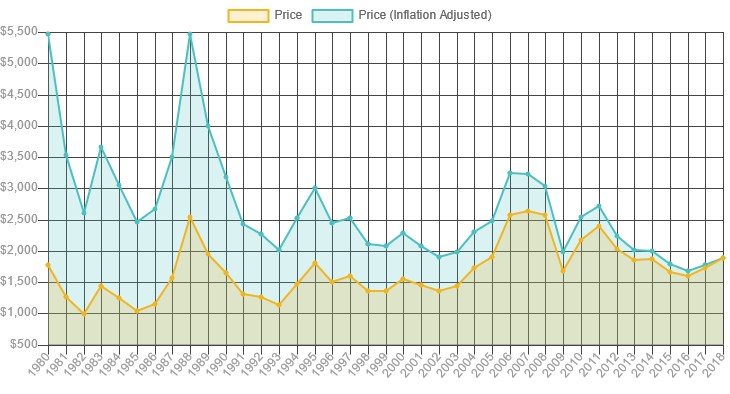

Scrap Aluminum Price

We search the world for the highest prices so that we can pass those high prices along to you! All of this translates to more money in YOUR pocket, right where it belongs! So if you are looking for the best scrap metal price anywhere in Victoria, give us a call today! Super Metal Recycling gives you best price for your scrap metals.

What’s the Price of Aluminium Cans?

Aluminium is the most common chemical element on this planet. People always don’t see the importance of their trash and the need for recycling. Did you know that you can recycle cans for cash? The aluminium can scrap price is higher than cast metal, and it is sold in terms of Kgs. You can change aluminium cans for cash and get some extra dollars.

Should We Recycle Aluminium Cans?

-

Aluminium recycling saves energy

Aluminium production takes a lot of energy which can be saved by recycling. Refining of aluminium metals is done using the hall method. Although, the method is faster and inexpensive as compared to refining aluminium from bauxite. The process requires a lot of energy before you get the best-refined aluminium that can be used. You end up using a lot of electricity to produce enough aluminium.

-

Aluminium recycling helps to reduction of waste and mining impacts

Mining of aluminium can cause environmental impacts. When mining for any mineral, the miners dig and drill tunnels to get to the minerals. This is the same way aluminium mining is done. Mining makes the environment look ugly since it is filled with the tunnels.

Additionally, when you are mining, there are a lot of wastes that is disposed to the environment. This destroys the beautiful, gorgeous scenery of nature. When aluminium is recycled the less, it will need to be mined, and this can save the environment and maintain the beautiful vegetation.

-

Aluminium recycling helps to reduction of production of carbon dioxide and carbon monoxide

Aluminium production using the hall process requires the current to pass through some electrodes. The reaction between the electrode and the molten alumina produce high amounts of carbon dioxide. Although aluminium is produced using this method. The production of carbon dioxide is a lot, and it is released to the atmosphere, and it causes global warming. Recycling of aluminium cans can reduce the amount of carbon dioxide produced in a day. This helps save and protect the environment.