Have you ever wondered what happens to old cars, scrap metal, or household appliances once they leave your hands? It’s more than just tossing them into a bin. Metal recycling is a fascinating process that turns what many see as waste into valuable resources, ready to be reused in new products. At its core, it’s about sustainability, efficiency, and a bit of clever technology.

Why Sorting Metal Matters

Not all metals are created equal. Steel, aluminium, copper, brass, and other alloys each have different properties and melting points. If they’re mixed together during recycling, the end product could be weak or unusable. That’s why careful sorting is the first and most critical step in metal recycling.

Sorting also protects the environment. Proper separation ensures harmful metals or coatings don’t contaminate recycled materials or the soil. Plus, it makes the recycling process more energy-efficient, saving both time and resources.

How Is Metal Collected and Prepared?

Metal usually comes from a variety of sources—old vehicles, construction sites, industrial machinery, and household items. When it arrives at a recycling facility, it’s first inspected for any non-metal components. Plastics, rubber, wood, and electronics are removed because they can interfere with processing.

For automotive scrap, this often means draining fluids like oil, fuel, and coolant. Batteries and tyres are separated and handled separately to prevent environmental hazards. Once cleaned, the metal is ready to move on to sorting.

What Methods Are Used to Sort Metal?

Sorting metal is both an art and a science. Modern facilities use a combination of manual and mechanical methods to separate different types of metals efficiently.

- Magnetic Separation:

Steel and iron are magnetic, so giant magnets can easily pull these metals from the mix. This is often the first sorting step because it quickly removes ferrous metals from non-ferrous ones. - Eddy Current Separation:

Non-magnetic metals like aluminium and copper are trickier. Eddy current separators create a magnetic field that repels non-ferrous metals, sending them to a separate collection line. It’s clever science in action and works surprisingly well for materials like aluminium cans and car parts. - Sensor-Based Sorting:

Some advanced recycling facilities use sensors that detect metals based on their chemical composition. X-ray, infrared, and optical sensors can identify metals with incredible precision, allowing for highly accurate separation. - Manual Sorting:

Even with all this technology, human hands still play a role. Workers inspect metal pieces, removing anything that machines might miss, such as mixed materials, hazardous parts, or oddly shaped pieces that need special handling.

How Is Metal Processed After Sorting?

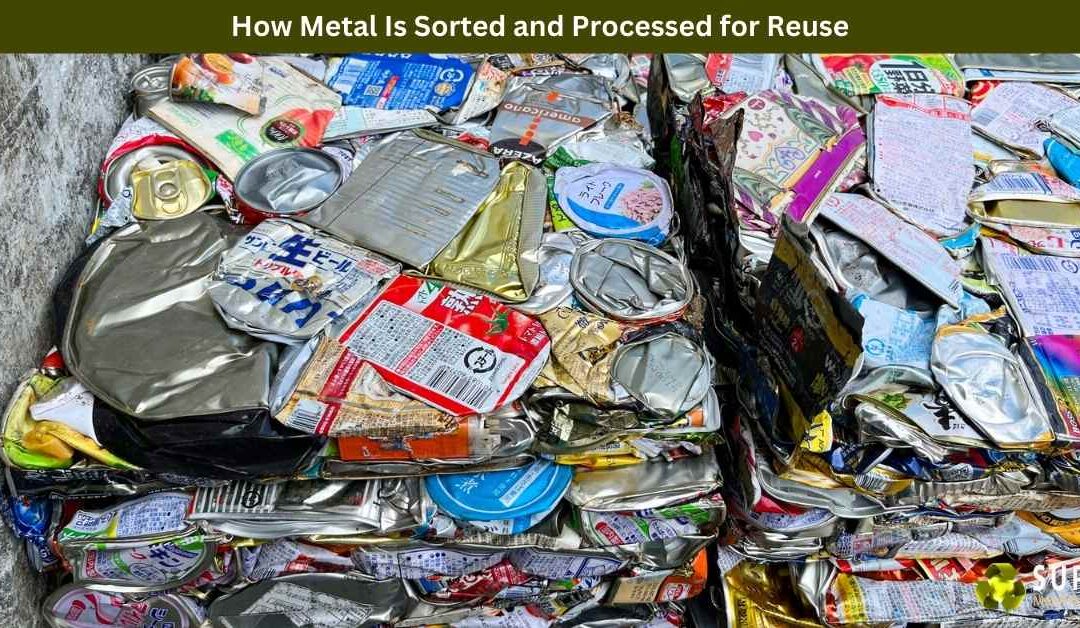

Once sorted, metals are shredded or crushed into smaller pieces. This step makes it easier to melt and recycle the material. Smaller pieces also allow for a more uniform melting process, producing high-quality recycled metal.

Next comes melting. Each metal type is heated in a furnace specifically designed for its properties. Aluminium, for example, melts at a much lower temperature than steel, so it requires a separate process. During melting, impurities are removed, ensuring the final product meets quality standards.

Finally, the molten metal is cast into blocks, sheets, or ingots, ready to be shipped to manufacturers. These recycled metals are often used in construction, automotive parts, packaging, and even new appliances. In many cases, recycled metal is indistinguishable from virgin metal, making it a win for both the industry and the environment.

How Does Metal Recycling Benefit You and the Environment?

Recycling metal isn’t just a behind-the-scenes operation. It has tangible benefits for everyone:

- Energy Savings: Recycling metal uses significantly less energy than producing new metal from raw ore. For instance, recycling aluminium saves up to 95% of the energy needed to make it from scratch.

- Reduced Landfill Waste: Every tonne of metal recycled keeps tons of waste out of landfills.

- Conservation of Natural Resources: Less mining means less environmental disruption and a smaller carbon footprint.

- Support for Local Industries: Recycled metal is a vital raw material for manufacturers, supporting jobs and the economy.

Can I Recycle Metal at Home or Through Local Services?

Absolutely! Many councils and private companies across Australia offer metal collection services. Old cars, scrap appliances, and even garden tools can often be collected and recycled safely. Using a reputable metal recycling service ensures that your scrap is processed correctly, without harming the environment.

For larger items like vehicles, automotive recycling companies often provide convenient pick-up services. These businesses handle everything from dismantling to sorting and ensure that valuable metals are efficiently recycled.

Recycling metal is a process that blends technology, expertise, and environmental care. From the moment scrap arrives at a facility to the point it’s transformed into usable materials, every step plays a vital role in giving metals a second life. So, next time you hand over an old car or appliance for recycling, remember—you’re contributing to a smarter, greener, and more sustainable future.

If you are in Cheltenham, and looking for a metal recycling service, this is the best way to visit us.

Super Metal Recycling

345 Frankston – Dandenong Road, Dandenong South VIC 3175

(03) 9706 4909

Recent Comments