Ever wondered what actually happens to your scrap metal once it leaves your hands? Metal recycling isn’t just about tossing old parts into a bin — it’s a carefully managed process that transforms unwanted metal into valuable new materials. From collection to melting, every stage plays a role in reducing waste and conserving natural resources. Here’s a clear look at how it all works.

How Does Metal Recycling Start?

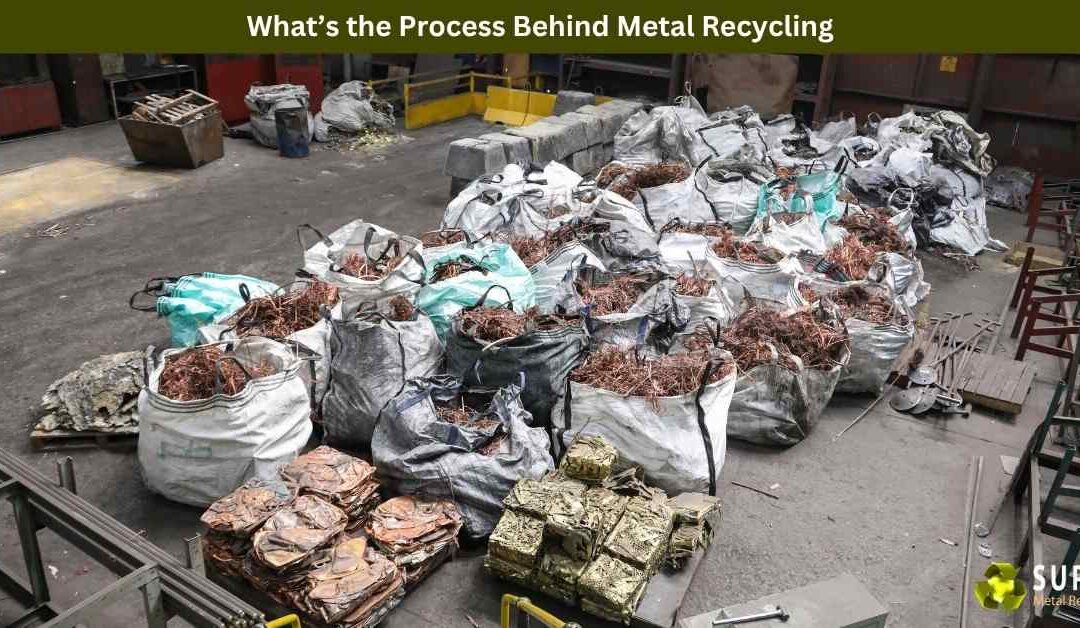

The process begins with collection. Scrap metal comes from various sources — everything from old vehicles, appliances, and construction materials to cans and machinery. Once gathered, it’s transported to a metal recycling facility, where the real work begins.

Metal recyclers buy, sort, and process metals like aluminium, copper, steel, and brass. Some materials are brought in by individuals cleaning out sheds or garages, while others come from demolition sites, factories, or car wrecking yards.

Step 1: Sorting the Metal

Sorting is one of the most important steps. Recyclers use magnets, sensors, and visual inspection to separate metals by type.

- Ferrous metals (like iron and steel) stick to magnets.

- Non-ferrous metals (like aluminium, copper, and brass) don’t.

Accurate sorting ensures the melted metal remains pure and can be used effectively in new manufacturing. For example, you don’t want traces of steel in recycled aluminium, as that would affect its strength and performance.

Step 2: Cleaning and Preparing

Before recycling, the metal must be cleaned of impurities such as paint, oil, rubber, or plastic. In some cases, items are shredded into smaller pieces to make melting faster and more efficient.

Think of it like preheating before cooking — breaking metal into manageable pieces helps maintain consistent temperatures and reduces energy use during melting.

Step 3: Shredding and Compacting

After cleaning, large metal items like car parts or beams go through industrial shredders or shears. This step:

- Reduces size for easier handling and transport.

- Increases surface area so metals melt more quickly.

- Prepares materials for the furnace stage.

Some recyclers compact light metals into dense cubes or bales to save space and improve furnace efficiency.

Step 4: Melting the Metal

Next, the sorted and shredded metal goes into a large industrial furnace designed for that specific type of metal. The metal is heated to its melting point, which varies depending on the material — for example, aluminium melts at around 660°C, while steel melts closer to 1,370°C.

This process takes energy, but it’s still far more efficient than creating new metal from mined ore. On average, recycling metal uses up to 90% less energy compared to refining raw materials.

Step 5: Purification and Refining

Once molten, the metal is purified to remove contaminants or unwanted alloys. Methods like electrolysis or magnetic separation help refine the metal to the desired quality.

This stage ensures the recycled metal performs just as well as new material. In fact, metals can be recycled indefinitely without losing quality — which is why metal recycling is such a key part of sustainable manufacturing.

Step 6: Solidifying and Shaping

After refining, the liquid metal is poured into moulds or cast into bars, sheets, or ingots. These solid blocks of recycled metal are then sold to manufacturers who use them to create new products.

It’s a full-circle moment — your old car panels or washing machine could soon be reborn as part of a new building frame, a bicycle, or even another car.

Step 7: Distribution and Reuse

Finally, the recycled metal enters the supply chain and is reused in industries like:

- Construction – for beams, pipes, and roofing.

- Automotive manufacturing – for engines and panels.

- Appliances and electronics – for wiring and casings.

- Packaging – especially for aluminium cans and containers.

This reuse not only reduces the need for mining but also keeps valuable materials circulating within the economy.

Why the Metal Recycling Process Matters

The recycling process might sound industrial, but it’s one of the most effective ways to protect the planet. Every tonne of recycled metal saves natural resources, cuts energy use, and reduces landfill waste. It’s also an important part of Australia’s circular economy — turning what was once considered waste into something useful again.

Metal recycling is a perfect example of how everyday materials can get a new lease on life through smart, sustainable practices. Whether it’s a crushed can, a rusted car, or leftover steel from a project, every piece of scrap has potential when it’s recycled the right way.

If you are in Springvale South, and looking for a metal recycling service, this is the best way to visit us.

Super Metal Recycling

345 Frankston – Dandenong Road, Dandenong South VIC 3175

(03) 9706 4909

Recent Comments